Cleanable & Hygienic keyboards for the food processing industry

Easy cleanable keyboards with stainless steel housing

NSI offers "food keyboards" specifically designed for the needs of the food processing industry and optimized to reduce contamination.

A touch screen seems to be the perfect solution for food applications, but it has limitations on ergonomics and usability. The combination of cold environments and 60 °C hot water for cleaning makes it a challenging environment.

NSI designed an IP65 sealed keyboard with an integrated waterproof trackball or a touchpad that can also be operated with gloves. The innovative waterproof breathable membrane on the back of the keyboard ensures a dry environment within the stainless steel housing with IP65 seal.

Perfect for the harsh conditions in the food processing industry, while still ensuring easy cleaning and hygienic design.

Panel mount keyboards

NSI offers industrial panel mount keyboards for a seamless integration into your equipment. We also have complete flat surface keyboards.

See our panel mount keyboards which are suited for food processing applications.

General features

- Easy cleaning and disinfection

- Hygienic design keyboards

- Completely flat surface keyboard

- Reducing the risk of cross-contamination

- Sealing IP65 up to IP68, completely waterproof

- Operating keyboards with gloves

- Stainless steel housing

CASE : Designing a custom keyboard solution for Puratos

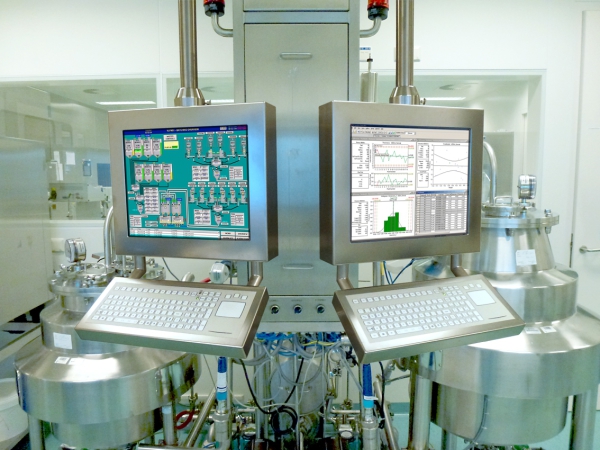

When Puratos, one of the biggest food ingredient suppliers in the world, modernized its machinery, Hygienic designed touchscreen displays, integrated with the company’s computer systems, were installed. This seemed like the perfect solution, given the hygienic requirements and harsh conditions within the production area.

These multi-touch screens have a few downsides though. It is a lot more ergonomic and comfortable for operators to work with a keyboard and mouse/trackball when entering large amounts of data. Furthermore, when the touch functionality does not fully work (due to pollution, malfunction, gloves,…) the operator station may go out of service.

Puratos began looking for a custom solution and landed on the NSI food keyboards. Because the touchpanels could be mounted in several ways, Puratos needed a custom solution to fit the keyboards onto its panel computers. NSI designed a frame that attached directly to the existing infrastructure, in every possible mounting form. The foldable design and adjustable angle of the frame provided an ergonomic advantage for the Puratos team. Even when the type of panels changes, NSI can quickly adapt the frame without high costs or efforts.

Steven Batselier - Automation Manager Puratos N.V.

“We wanted to make life easier for our operators by installing keyboards next to our existing displays. Finding products that fit the hygienic needs within the food industry wasn’t easy. Finding the right mounting onto our panels was even a lot more difficult. But when we landed on the NSI website we found what we were looking for.

They really made a difference by designing a custom-made frame to mount the keyboards on our existing displays. It was tested thoroughly in our facilities to make sure both the frame and the keyboards met our standards. Everything was installed and delivered within two days after testing. NSI offered great service.”